Product Introduction Of Impact Mill Rock Crusher:

The Impact crusher machine we produce is a crushing machine that uses impact energy to crush materials. Impact Crusher is mainly used to crush tough materials such as limestone and shale. Impact crusher machine can be used in conjunction with a roller feeder to form a special crushing system. Vertical impact crusher is mainly composed of a frame, a transmission mechanism, a rotor, a hammer head and an impact plate. Impact mill rock crusher reduces noise and dust emissions while reducing energy consumption, meets environmental protection requirements, and achieves green production.

Impact Crusher Machine Parameters:

| Specification Of Impact Rock Crusher | Maximum Feed Size Of Impact Rock Crusher(Mm) | Discharge Size Of Horizontal Impact Crusher(Mm) | Production Capacity Of Horizontal Impact Crusher(T/H) | Main Engine Power Of Horizontal Impact Crusher(Kw) |

| PF1210 | 325 | 25-80 | 50~70 | 132 |

| PF1214 | 325 | 25-80 | 90~145 | 132 |

| PF1315 | 325 | 25-80 | 100~250 | 200 |

| PF1320 | 325 | 25-80 | 280~320 | 400 |

| NPF1412 | 600 | 25-80 | 100~150 | 160-185 |

| NPF1416 | 600 | 25-80 | 180~220 | 355 |

| NPF1616 | 800 | 25-80 | 250~350 | 450 |

| NPF1618 | 800 | 25-80 | 350~400 | 500 |

| NPF1820 | 1000 | 25-80 | 450~650 | 710 |

| NPF1822 | 1000 | 28-80 | 600~800 | 800 |

| NPF2022 | 1500 | 25-100 | 800-1000 | 1250 |

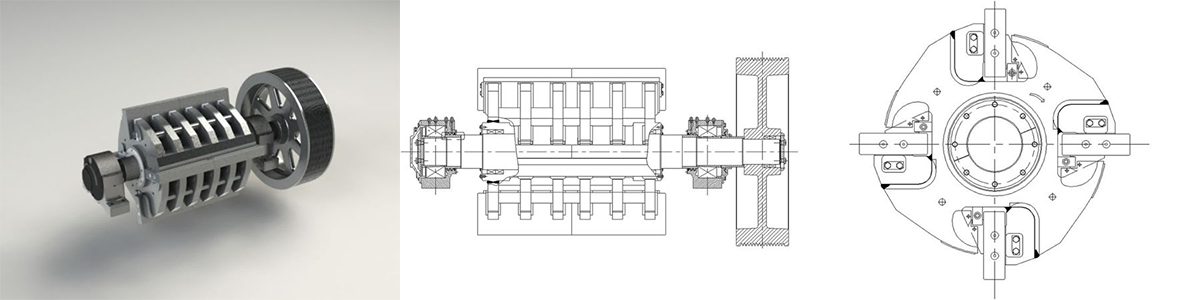

Components Of Impact Mill Rock Crusher:

Rotor:

As the key part of the impact crusher, the rotor driven blow bar is used to hit material at a high speed until it is crushed.

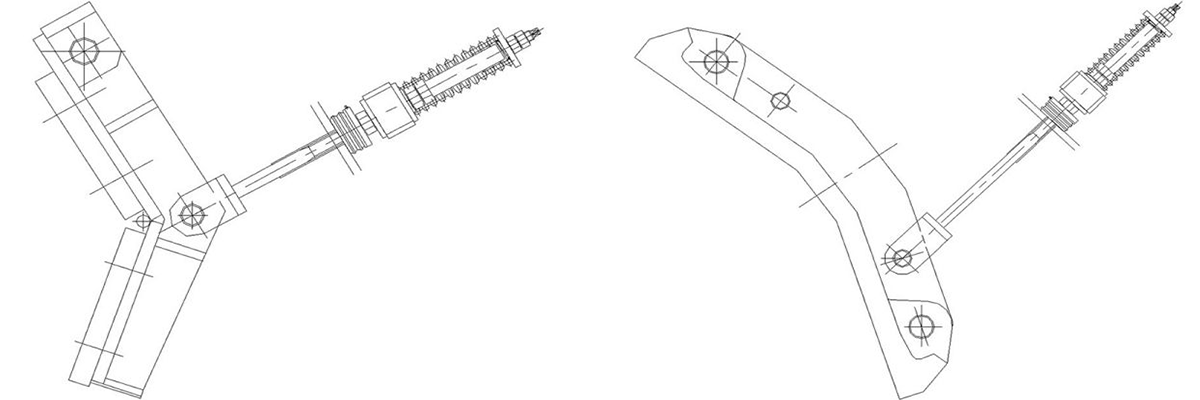

Impact Plate:

There are two impact plates at the front and back of the impact crusher, which are designed to endure a high impact. The impact plate is designed with a cushioning adjustment structure in order to enhance the wear resistance.

Features Of Horizontal Impact Crusher:

The impact mill rock crusher we produce can be used to deal with mining ores with high hardness and strong abrasiveness, and can crush hard rocks with a compressive strength of up to 250Mpa.

The impact crusher machine uses high-speed rotating rotors and plate hammers to generate impact energy, so that the materials repeatedly collide and rub in the crushing chamber of the impact mill rock crusher, thereby achieving an efficient crushing effect.

Compared with ordinary crushers, the vertical impact crusher we produce has good crushing performance, high material adaptability, flexible adjustment of the discharge particle size, and convenient maintenance.

The impact mill rock crusher plays an important role in mining, metallurgy, construction and other fields.

Precautions For Horizontal Impact Crusher:

Impact crusher machine equipment inspection: Before starting the machine, the fasteners, transmission parts and wear parts of the impact rock crusher should be fully inspected.

Lubrication inspection of impact crusher: Check whether there is enough lubricating oil at each lubrication point of impact rock crusher, the connecting bolts must be tightened, and each door must be closed.

Inspection of wearing parts of impact crusher machine: Regularly check the wear of wearing parts of impact rock crusher such as plate hammer and impact liner. If serious wear is found, it should be replaced in time to avoid affecting the normal operation of impact rock crusher.

About Us:

Liyang Sinoma is an international engineering service provider integrating development and design, processing and manufacturing of vertical impact crusher, complete engineering and technical consulting services. The leading product vertical impact crusher covers cement, metallurgy, mining, electricity, coal, chemical industry and environmental protection. In terms of logistics, the company pays attention to environmental protection in the logistics process and adopts sustainable transportation and packaging methods, which helps to reduce the impact on the natural environment. We are a company specializing in the production of vertical impact crusher and other mechanical equipment, and hope to have the opportunity to cooperate with you.