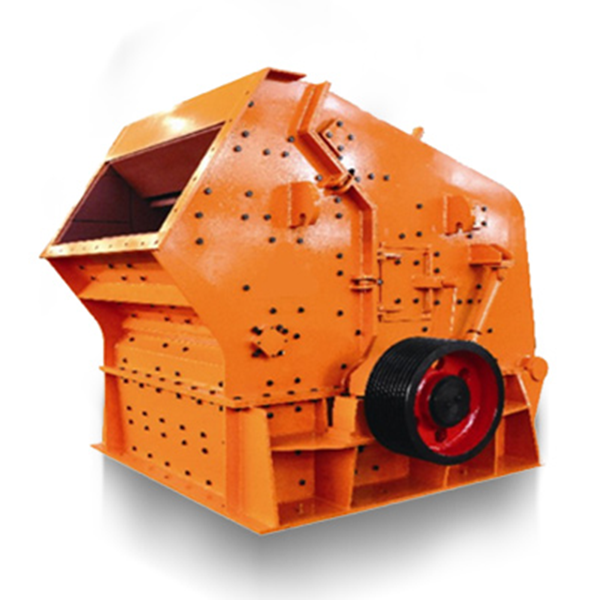

In the ore crushing and building materials processing industries, horizontal impact crusher is one of the key equipment. However, many buyers found that the service life of horizontal impact crusher was much lower than expected during use. This not only affects production efficiency, but also increases the cost of impact crusher machine maintenance and replacement. So, what factors affect the service life of horizontal impact crusher Understanding these three key factors will help you maximize the value of horizontal impact crusher and extend its service life.

1. The key role of the hammer material

The hammer is the core component of impact mill rock crusher, and its material directly determines the durability and crushing efficiency of impact mill rock crusher. Low-quality horizontal impact crusher hammers are prone to wear or breakage under high-intensity working conditions, thereby shortening the service life of impact mill rock crusher. The horizontal impact crusher hammer we provide is made of high-strength alloy steel material, which has excellent wear resistance and impact resistance after special treatment. This high-quality horizontal impact crusher hammer can maintain high efficiency and stability during the crushing process of various ores and rocks, greatly extending the service life of impact mill rock crusher.

2. The influence of material properties

The characteristics of the crushing material, such as hardness, moisture and abrasiveness, have a direct impact on the service life of impact mill rock crusher. Materials with higher hardness or containing a large amount of abrasive substances will aggravate the wear of impact crusher machine. We provide customers with detailed material analysis and crushing process recommendations to help choose the right impact mill rock crusher configuration. By optimizing the material pretreatment and crushing process, you can significantly reduce the wear of impact crusher machine and improve the durability and economy of the equipment.

3. The importance of regular maintenance

Equipment maintenance is essential to ensure the long-term and stable operation of impact mill rock crusher. Lack of regular maintenance may cause accelerated wear of horizontal impact crusher components and even failure. Our maintenance services include regular inspections, component replacements, and system optimization to ensure that impact mill rock crusher is always in optimal operating condition. Through professional maintenance, you can effectively reduce the failure rate and production downtime, thereby improving overall production efficiency.

The service life of impact crusher machine is affected by three main factors: the material of the hammer, material properties, and equipment maintenance. Selecting high-quality impact crusher machine hammer materials, optimizing material processing processes, and performing regular maintenance are the key to ensuring the long-term and efficient operation of impact crusher machine. We are committed to providing every customer with the best products and services to help you maximize the value of your equipment and extend its service life. If you are also interested in Impact Crusher machine and other products and equipment, please feel free to contact us!