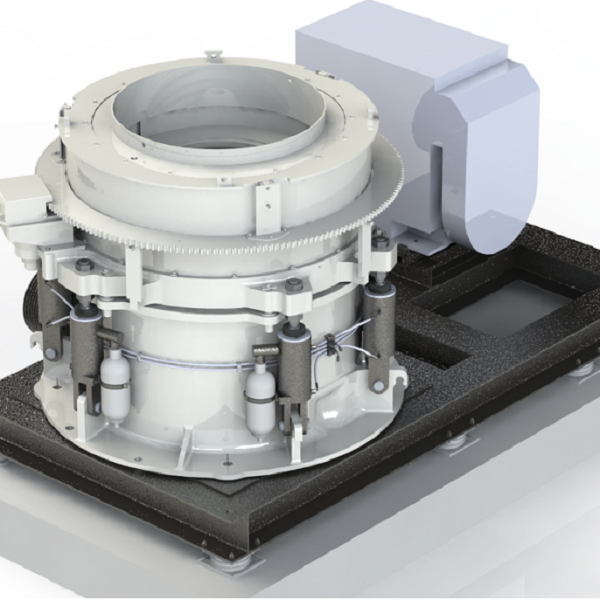

Cone crusher machine is one of the core equipment in the mining, building materials and metallurgy industries. However, the efficient operation of the equipment is often affected by inadequate maintenance, resulting in frequent failures and reduced production efficiency. Are you troubled by the failure of cone crusher machine? Today, we will discuss in depth the maintenance methods of cone crusher machine's lubricating oil replacement and discharge port adjustment to help you manage the equipment efficiently and extend its service life.

1. Lubricant Replacement

Lubricant plays a vital role in the operation of the cone crusher machine. It not only reduces friction, but also effectively dissipates heat to prevent the cone crusher machine from overheating. In order to ensure the smooth operation of the cone crusher machine, it is necessary to replace the lubricant regularly. We recommend that you follow the steps below:

Regular Inspection:According to the frequency of use of hydraulic cone crusher, it is recommended to check the condition of lubricating oil every month. Observe the color and viscosity of the oil. If it becomes black or thick, it means that it needs to be replaced.

Choose the Right Oil:Ensure that high-quality lubricating oil that meets the requirements of hydraulic cone crusher is selected to enhance the performance of hydraulic cone crusher.

Replacement Process: When replacing, first completely drain the old oil, clean the oil tank and filter of hydraulic cone crusher, ensure the purity of the new oil, and avoid impurities from damaging hydraulic cone crusher.

2. Adjustment Of The Discharge Port

The setting of the discharge port directly affects the crushing effect and output of the portable cone crusher. An unreasonable setting of the discharge port may lead to poor material discharge, thereby reducing production efficiency. The following are the key steps to adjust the discharge port:

Regular Inspection: During the operation of the portable cone crusher, regularly check the size of the discharge port to ensure that it meets production needs.

Adjustment Method:By adjusting the adjustment bolts on the base of the portable cone crusher, the width of the portable cone crusher discharge port can be easily changed. According to the nature and requirements of the crushed material, timely adjustments should be made to ensure that the crushing effect is optimal.

Record Data: After each adjustment, record the setting data of the portable cone crusher discharge port for subsequent reference to ensure production consistency.

By regularly changing the lubricant and adjusting the discharge port, you can significantly improve your portable cone crusher's operating efficiency and equipment life. As a leader in the industry, our company is committed to providing you with the most professional equipment maintenance solutions and high-quality products. When you choose us, you will receive reliable technical support and high-quality after-sales service to help you continuously improve your production and create greater value. If you are also interested in our portable cone crusher, please feel free to contact us!