In today's construction industry, the demand for cement as a basic material continues to grow, and cement mills, as key equipment in the cement production process, play a vital role. The production process of cement mills involves a variety of technical links, from the grinding of raw materials to the manufacture of finished cement, and each step affects the quality and production efficiency of the final product. This article will explore in depth the working principle of cement mills and the role they play in the production process.

Raw Material Preparation Process:

The production of cement mills first requires the preparation of cement clinker, which is made from raw cement powder is to send the raw materials into the crushing equipment for preliminary crushing, and then transport the crushed raw materials to the clinker warehouse for storage through a conveyor belt.

Grinding Process:

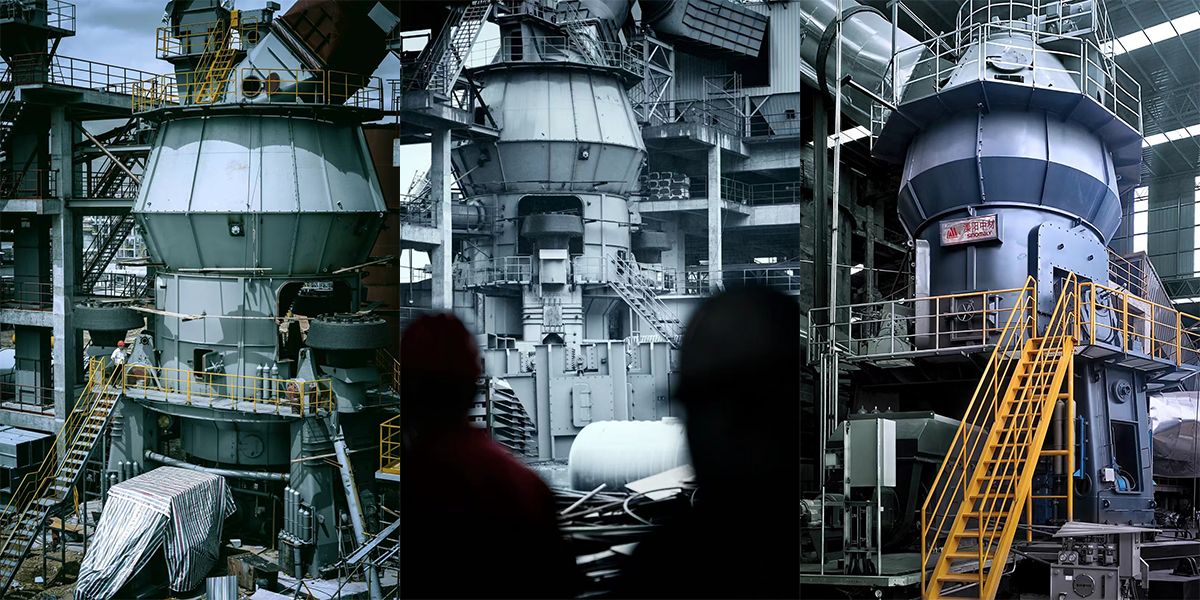

The clinker will be transported from the clinker warehouse to the cement mill for grinding. The clinker in this process will enter the cement mill together with the grinding media (such as steel balls or grinding bodies) and appropriate additives. Under the high-speed rotation of the grinding disc and the drum, the clinker is ground into finer cement powder.

Primary Product Grinding Process:

After the initial grinding is completed, the obtained cement powder does not meet the standards of the final product, so further grinding is required. This process is usually completed in a classifier, which classifies the cement powder by particle size and separates qualified fine powder from unqualified coarse powder to meet cement powder with different particle size requirements.

Screening Process:

The screening process is immediately after the grinding process. The screening equipment will remove the over-coarse or over-fine particles in the cement powder to ensure that the product has uniform particle size and meets the standard requirements.

Packaging Process:

The last step in cement production is packaging. In this link, the screened cement powder will be sent to the automatic packaging machine for bagging, and then stacked for transportation and finally sent to the sales market.

Although the production process of cement mill is complicated, every link is carefully designed and operated to ensure the high quality and efficient production of the final product. The vertical cement mill we launched is a modern grinding equipment that integrates high efficiency, energy saving and environmental protection. It is suitable for grinding a variety of materials such as cement, raw materials, coal and slag. The equipment has a high degree of automation and is easy to use, which can greatly improve production efficiency. If you are interested in our products, please feel free to contact us! Looking forward to providing you with more detailed information and support, I hope this introduction will help you better understand the cement mill.