In industrial production, hammer crusher machine is a key equipment for processing solid waste and ore. Its selection is crucial to production efficiency and the quality of the final product. However, facing the wide variety of crusher models on the market, how to choose the most suitable equipment has become the focus of many companies. Industry experts point out that when choosing hammer crusher machine, it is necessary to comprehensively consider multiple aspects such as raw material properties, production requirements, and equipment performance.

The first thing to consider is the nature of the raw materials. The type, hardness, water content, degree of cleavage, etc. of the material directly affect the selection and effect of the hammer crusher machine. For example, materials with higher hardness require the selection of a crusher with strong wear resistance, while materials with higher water content need to consider the anti-clogging performance of the Hammer crusher machine. Therefore, in-depth understanding of the characteristics of the material to be processed is the first step in crusher selection.

Production scale and product requirements are important bases for the selection of hammer crusher machine. Different production scales correspond to different models and specifications of Hammer crushing machine, and the particle size and particle size composition of the crushed product also directly determine the configuration of the equipment. For example, if the company has high requirements for the particle size of the product, it is necessary to choose equipment that can achieve fine crushing.

The price, brand awareness and after-sales service of the equipment are also important factors in the selection of Hammer crushing machine. Although the price of high-quality brand hammer crusher machine may be higher, its stable performance, durability and perfect after-sales service can effectively reduce the long-term maintenance cost and ensure the long-term and efficient operation of the hammer mill rock crusher.

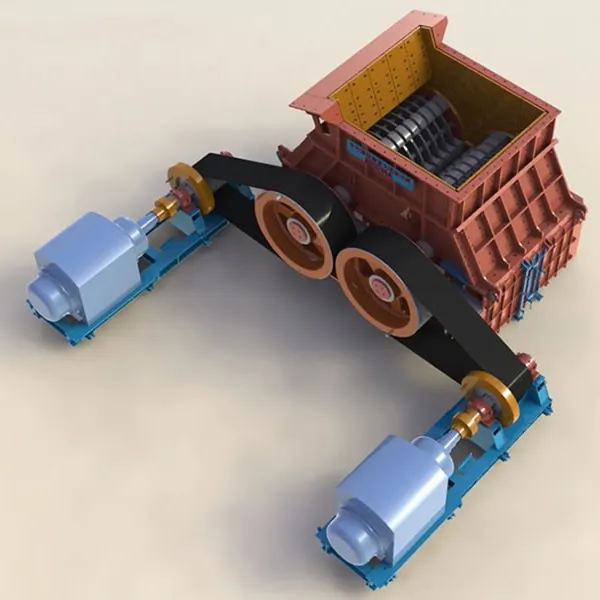

In addition, the technical parameters and performance of the Hammer crushing machine, such as crushing capacity, particle size, and particle size requirements of the crushed product, are also factors that must be considered when selecting equipment. The feeding method and the conditions of the installation and operation site should not be ignored either, as they directly determine the working efficiency and applicability of hammer crushing machine.

Through our sharing, I believe that everyone has learned about how to choose hammer mill rock crusher, and I hope that our article can help you. The Hammer crushing machine produced by our company has been widely used in many industries. Not only does it have fewer wearing parts and convenient maintenance, it can also meet the crushing needs of various materials. At the same time, the design of the hammer mill rock crusher fully sealed body structure makes the equipment more in line with the standards of green and environmentally friendly production, helping enterprises achieve efficient and environmentally friendly production goals. If you are interested in our hammer mill rock crusher, please contact us!