Are you confused about the difference between primary gyratory crusher and cone crusher when choosing crushing equipment? These two devices play an important role in different application scenarios, and understanding their core differences will help you make a wise purchasing decision. We will analyze the characteristics of these two devices, gyratory crushing machine and cone crusher, from multiple angles to help you find the equipment that best suits your production needs.

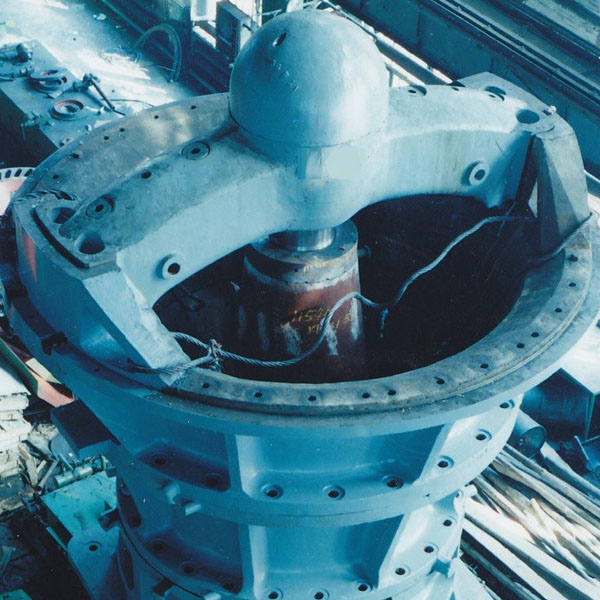

The crushing chamber of primary gyratory crusher is relatively large in shape and is designed to handle larger pieces of material, providing higher processing capacity. The shape of gyratory crushing machine allows the material to stay in the chamber for a longer time during the crushing process, thereby achieving higher crushing efficiency. In contrast, the crushing chamber of cone crusher is relatively compact and suitable for handling small pieces of material. The unique chamber design of cone crusher allows materials to be crushed more quickly, which is suitable for fine crushing and medium-hard materials.

In terms of the hood movement speed, the hood movement speed of primary gyratory crusher is relatively slow, which makes it suitable for occasions that require long-term crushing. The hood movement speed of Cone Crusher is faster, which can complete the crushing of materials more quickly. This speed difference directly affects the production efficiency of the crusher. You can choose the appropriate equipment type according to actual needs.

Gyratory crushing machine usually uses a hydraulic system to adjust the discharge port, which makes the operation more convenient and gyratory crushing machine can quickly adapt to different production needs. Cone Crusher often uses mechanical methods to adjust the discharge port. Although the operation is relatively simple, it may affect efficiency when the adjustment frequency is high. Understanding the characteristics of these two adjustment methods can help you make a decision that better meets your production needs when selecting equipment.

Understanding the difference between primary gyratory crusher and cone crusher is the first step to achieve efficient production. Choosing the right equipment will directly affect your production efficiency and cost-effectiveness. If you are looking for a crusher that can provide excellent performance for your production line, you may wish to contact us. We will provide you with detailed technical support and professional advice to help you stay invincible in the highly competitive market. Looking forward to working with you to jointly promote the continued growth of your business and achieve higher production goals!