Production status of Sinoma- Liyang Heavy Machinery in December: Go all out to win the year-end victory

Time flies, and the calendar turns! As the last page of 2025 is about to be turned, Liyang Sinoma Heavy Machinery, with innovation as its brush and hard work as its ink, has written a remarkable chapter in the field of heavy equipment manufacturing. This year, we have delved deeply into core areas such as cement and building materials, as well as environmental protection in mining. From the successful authorization of multiple invention patents to the implementation of projects in more than 50 countries and regions worldwide, and from being recognized as a national "specialized, refined, unique, and innovative" enterprise to being awarded the honor of being a national high-tech enterprise, every step forward is engraved with perseverance and breakthroughs. On this occasion of ringing out the old and ringing in the new, we look back on our journey of hard work and look forward to embarking on a new journey with great anticipation.

PART 01 Installation and Commissioning Site

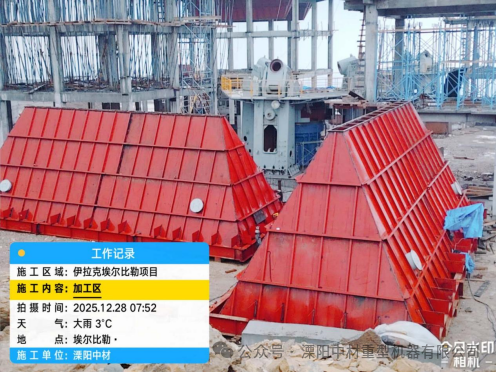

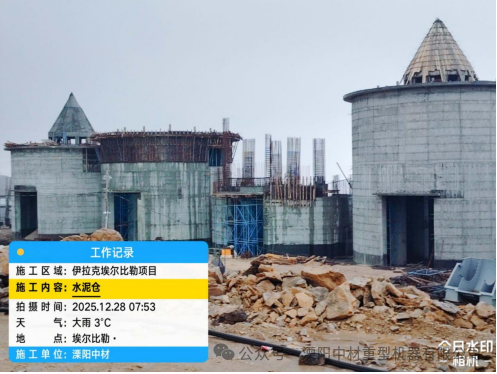

(1) Construction site of the Erbil cement grinding project in Iraq

(2) Construction site of the ANGREN UZKABLE 2500-ton/day clinker cement production line renovation project

PART 02 Items to be shipped

(1) Conveying products

Apron feeder

The apron feeder is widely used in industries such as mining, cement, metallurgy, coal, and chemical engineering. Our company designs and produces a series of products with complete specifications to meet the needs of different customers. The equipment has been awarded the honor of being designated as a recommended product by the China National Building Materials Bureau Cement Association.

Stacker-reclaimer and batch delivery

This series of products includes various types such as circular stacker-reclaimers, side cantilever stackers, side scraper reclaimers, bridge scraper reclaimers, arm-type bucket wheel stacker-reclaimers, bridge bucket wheel reclaimers, gantry scraper reclaimers, top-stacking and side-reclaiming stacker-reclaimers, and roller reclaimers, which are widely used in stockyards of industries such as steel, chemical, cement, mining, and coal.

(2) Crushing products

Impact Crusher

This product is suitable for crushing various materials with a compressive strength not exceeding 320MPa. It features a large crushing ratio, uniform product granularity, simple structure, reliable operation, easy maintenance, and economical operating costs. It is widely used in mining, metallurgy, building materials, highway, railway, water conservancy, and chemical industries. Our company can design and manufacture jaw crushers of various specifications, with a production capacity up to 1,500t/h.

(3) Thermal engineering products

Rotary kiln

The cement rotary kiln is a crucial equipment in both dry and wet cement clinker production lines, characterized by excellent calcination quality and high product quality. This equipment is widely used in the cement industry. The transmission device utilizes high-torque drive and features a slow start-up function; the kiln head and tail are made of specialized sealing materials that are resistant to wear, high temperature, air leakage, and ash leakage; the large gear ring can adopt a SEW segmented structure, ADI material, high-precision, low-noise, and high-efficiency gear ring drive scheme. After years of accumulation, our company can design and manufacture rotary kilns with diameters ranging from Φ2m to Φ6.2m. Additionally, we are capable of designing and producing various multi-channel pulverized coal burners, preheaters, and other auxiliary equipment for sintering systems, as well as metallurgical rotary kilns and various hazardous waste kilns.

(4) Grinding products

Ball mill

The ball mill produced by our company is designed to maximize the advantages and minimize the disadvantages inherent in open-flow grinding systems. The equipment utilizes hybrid or fully hydrostatic bearings, multiple drive configurations, and incorporates new wear-resistant materials and processing techniques. This product boasts high output and low energy consumption. Currently, our company is capable of designing and manufacturing ball mills ranging from Φ4m to Φ8m.

Others:

Shield machine

Bucket Wheel Stacker-Reclaimer